Plates/Shells - Results

When the model is solved, there are

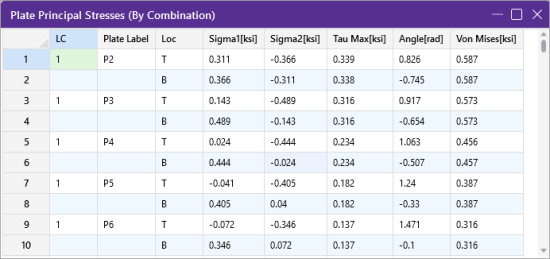

Plate Stress Results

To access the Plate Principal Stresses results spreadsheet:

-

Click on Results in the Explorer panel to expand Env (Envelope) results.

-

Click on Plate Stresses to open the Plate Stresses spreadsheet.

Click on image to enlarge it

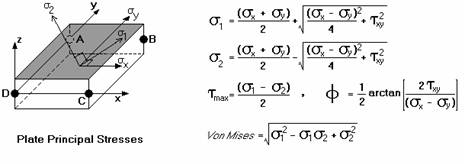

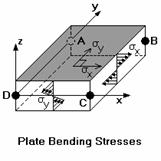

The plate stresses are listed for the top and bottom of each active plate. The principal stresses sigma1 (σ1) and sigma2 (σ2) are the maximum and minimum normal stresses on the element at the geometric center of the plate. The Tau Max (tmax) stress is the maximum shear stress. The Angle entry is the angle between the element's local x-axis, and the direction of the σ1 stress (in radians). The Von Mises value is calculated using σ1 and σ2, but not σ3 which isn't available for a surface (plate/shell) element, so this Von Mises stress does not include any transverse shear forces.

The equations are:

The angle, Φ, is the angle in radians between the maximum normal stress and the local x-axis. The direction of the maximum shear stress, tmax, is ± π/4 radians from the principal stress directions.

The Von Mises stress is a combination of the principal stresses and represents the maximum energy of distortion within the element. This stress can be compared to the tensile yield stress of ductile materials for design purposes. For example, if a steel plate has a tensile yield stress of 36ksi, then a Von Mises stress of 36ksi or higher would indicate yielding of the material at some point in the plate.

The σx , σy , and σxy values used to calculate the stresses are a combination of the plate bending and membrane stresses, thus the results are listed for the top and bottom surfaces of the element. The “Top” is the extreme fiber of the element in the positive local z direction, and the “Bottom” is the extreme fiber of the element in the negative local z direction. The membrane stresses are constant through the thickness of the element, while the bending stresses vary through the thickness of the element, very similar to the bending stress distribution in a beam.

For enveloped results the maximum and minimum value at each location is listed. The load combination producing the maximum or minimum is also listed, in the "LC" column.

- See Spreadsheet Operations to learn how to use Find, Sort and other options.

- See Results View Settings to learn how to plot Plate Stress results.

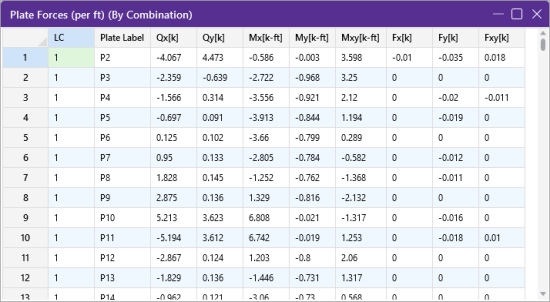

Plate Force Results

To access the Plate Forces spreadsheet:

-

Click on Results in the Explorer panel to expand Env (Envelope) results.

-

Click on Plate Stresses to open the Plate Stresses spreadsheet.

Click on image to enlarge it

The Plate Forces are listed for each

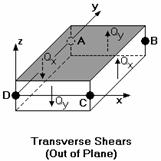

The forces (Qx and Qy)

are the out-of-plane (also called “transverse”) shears that occur through

the thickness of the element. The Qx shear occurs on

the element faces that are perpendicular to the local x-axis, and the

Qy shear occurs on the element faces that are perpendicular

to the local y-axis. Qx is positive in the z-direction

on the element face whose normal vector is in the positive x-direction.

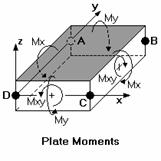

The plate bending moments (Mx,

My and Mxy) are the plate forces that induce linearly

varying bending stresses through the thickness of the element. Mx

is the moment that causes stresses in the positive x-direction on the

top of the element. Likewise, My is the moment that causes

stresses in the positive y-direction on the top of the element.

Mx can then be thought of as occurring on element faces that

are perpendicular to the local x-axis, and the My moment occurs

on faces that are perpendicular to the local y axis. To calculate

the total Mx or My on the face of an element, multiply

the given value by the length of the element that is parallel to the axis

of the moment. For example, looking at the 'Plate Moments' figure above,

the total Mx moment could be obtained by multiplying the given

Mx force by the length of side BC (the distance from

The Mxy moment is the out-of-plane twist or warp in the element. This moment can be added to the Mx or My moment to obtain the 'total' Mx or My moment in the element for design purposes. This direct addition is valid since on either the top or bottom surface, the bending stresses from Mxy will be going in the same direction as the Mx and My moments.

- For the placement of concrete reinforcement, it is helpful to realize that laying reinforcement parallel to the local x-axis will resist the Mx moment.

- A positive Mx or My moment will put the top fiber of the plate in tension.

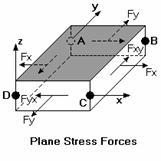

The plane stress forces (Fx , Fy and Fxy) are those forces that occur in the plane of the plate. These forces, which are also called “membrane” forces, are constant through the thickness of the element. Fx and Fy are the normal forces that occur respectively in the direction of the local plate x and y-axes, positive values indicating tension. These forces are reported as a force/unit length. To get the total force on an element, you would need to multiply the given value by the length of the element that is perpendicular to the normal force. For example, looking at the 'Plane Stress Forces' figure, the total Fx force could be obtained by multiplying the given Fx force by the length of side BC (the distance from joint B to joint C).

The Fxy force is the in-plane shear force that occurs along the side of the element. The subscript 'xy' indicates that the shear occurs on the face of the element that is perpendicular to the x-axis and is pointing in the y-direction. Fyx is the complementary shear force, where the subscript 'yx' indicates that the shear occurs on the face of the element that is perpendicular to the y-axis and is pointing in the x-direction. RISA-3D only gives values for Fxy because Fxy and Fyx are numerically equal. The total in-plane shear can be obtained by multiplying the given force value by the length of the element that is parallel to the shear force. For example, when looking at the 'Plane Stress Forces' figure, the total Fxy force which is parallel to the local y-axis could be obtained by multiplying the given Fxy force by the length of side BC.

Note that the

For enveloped results the maximum and minimum value is listed. The load combination producing the maximum or minimum is also listed, in the "LC" column.

- See Spreadsheet Operations to learn how to use Find, Sort and other options.

- See Results View Settings to learn how to plot Plate Force results.

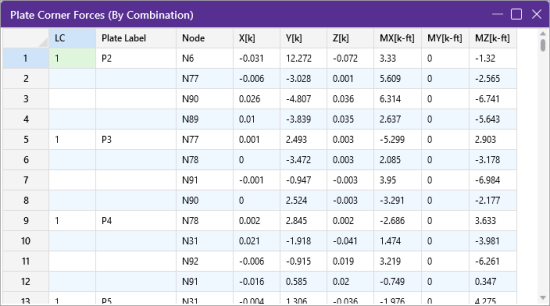

Plate Corner Force Results

To access the Plate Corner Forces spreadsheet:

-

Click on Results in the Explorer panel to expand Env (Envelope) results.

-

Click on Plate Stresses to open the Plate Stresses spreadsheet.

Click on image to enlarge it

The plate corner forces are the global forces at the corner of each

plate

These are the forces and moments calculated at the corners of the plates,

in the GLOBAL directions. These values are obtained by multiplying

the plate's corner displacements with the global stiffness matrix.

Unlike the local

As an example of how to use these corner forces, you can obtain the total shear at a given level in a shear wall by adding the proper corner forces for the plates at that level. See Plate Modeling Examples to learn how to use the plate corner forces to get shear wall story shears and moments, as well as slab moments and shears.

- See Spreadsheet Operations to learn how to use Find, Sort, Label Marked Lines in Current ViewShow Selected Lines in Current View and other options.

- See Results View Settings to learn how to plot Plate Corner Force results.